It’s just as true in Formula 1 as it is in RC…the longer a rule set stays consistent, the more the cars converge in terms of design (and generally performance). Designers and manufacturers figure out the best way to build race cars to a rule set, and over time the designs become more and more similar, and more and more mature.

Early in the life of a rule set or category, innovation happens in leaps and bounds, but later it becomes innovation by iteration: small changes, tiny tweaks, and minor adjustments in weight bias, geometry, and materials. In the end, it’s the fine details that matter.

There’s an argument to suggest that’s precisely where 8th buggy design is now. The rules have been stable for so long that, broadly speaking, designs have converged – and most manufacturers are offering a similar platform.

The one aspect where that’s not quite true yet is in the chassis layout for electric 8th buggies. There are still some divergent views on motor positioning, battery type and layout between manufacturers. For years it was the 4s brick pack that ruled the roost. Serpent were one of the first, more than 10 years ago, to experiment with saddle pack layouts. While recent releases have been trending more in the saddle pack direction, there’s still some divergence.

For a new manufacturer, like Sparko, all of this means a fascinating combination of following well-established class norms, rather than reinventing the wheel, and paying attention in the areas (like battery format and location) that aren’t quite yet settled.

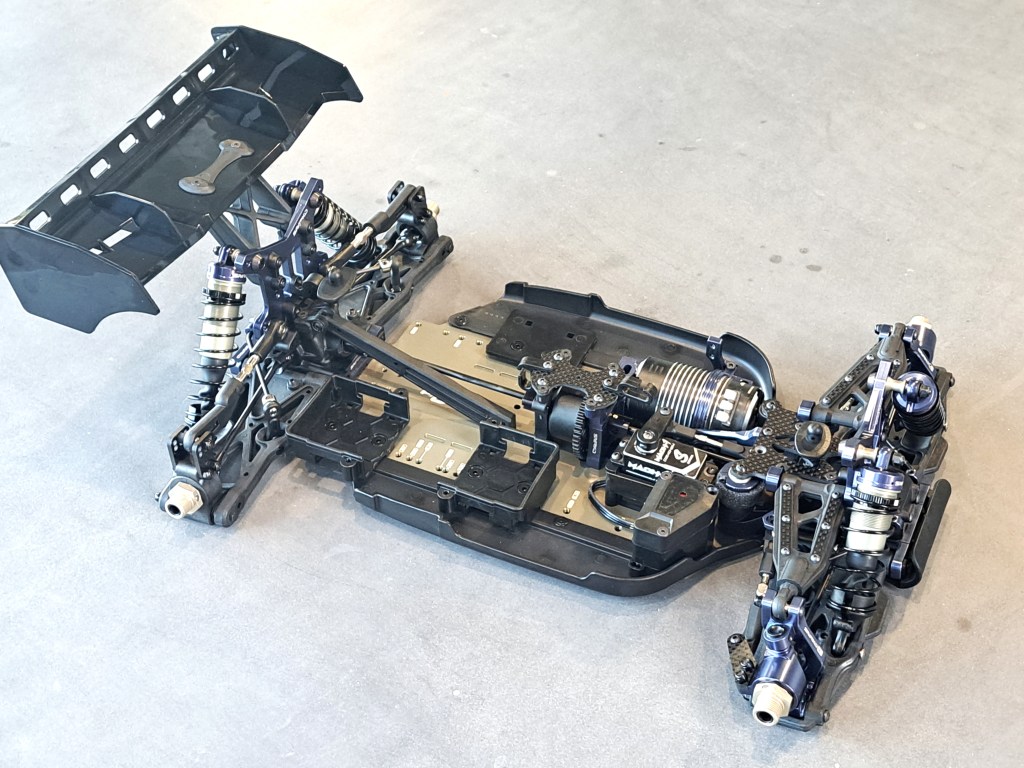

The F8e is Sparko’s first entry into the incredibly competitive world of eBuggy racing. Coming on the back of their nitro entrant (of course known as the F8), the F8e sticks with tried and true, and bulletproof conventions of the category. That, of course, means the class-standard drive-train layout, shock designs etc etc etc. If you’ve looked at an 8th buggy in the last 30 years, the Sparko holds no surprises in terms of major design aspects. We’ll get to their choices in terms of EP components and chassis layout in a minute.

All of that background, as we dive into this build review, means we focus on three things: execution (material quality, construction), small details (innovation by iteration), and the build experience itself (fit and finish, instructions and so on).

THE EXECUTION

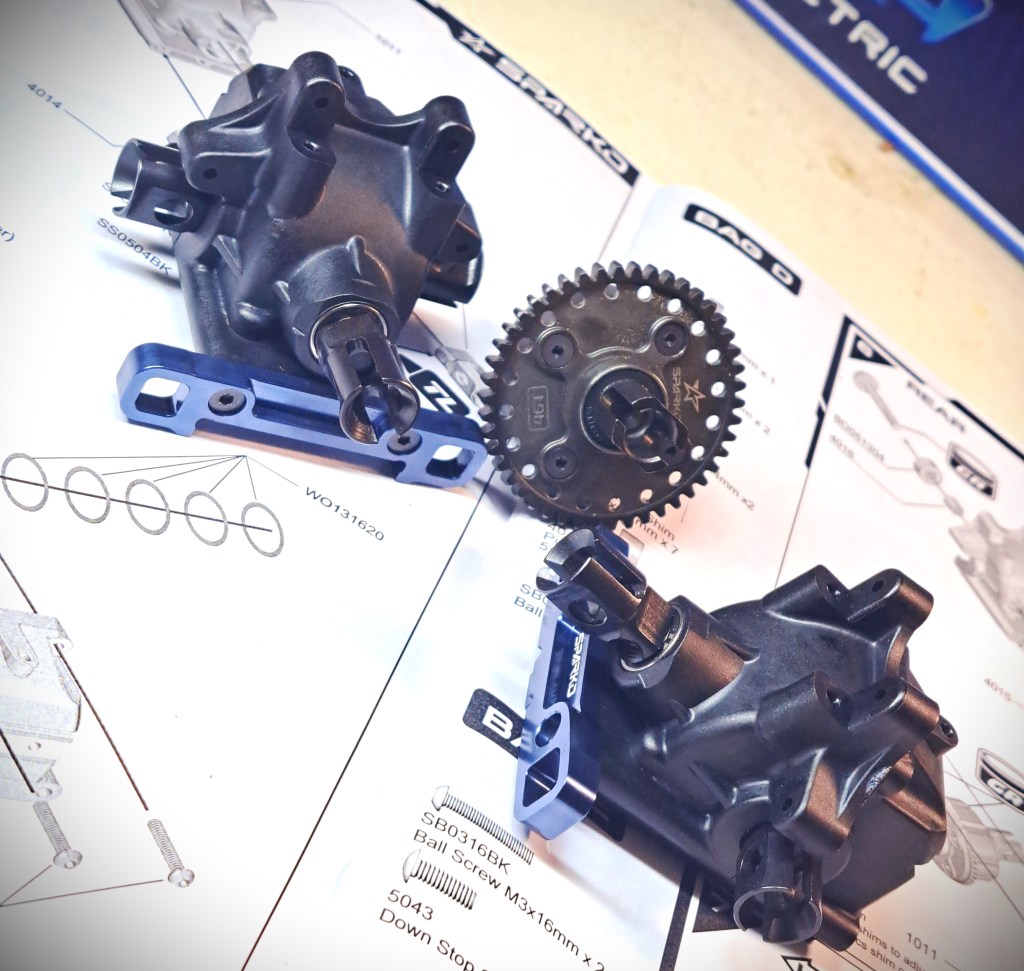

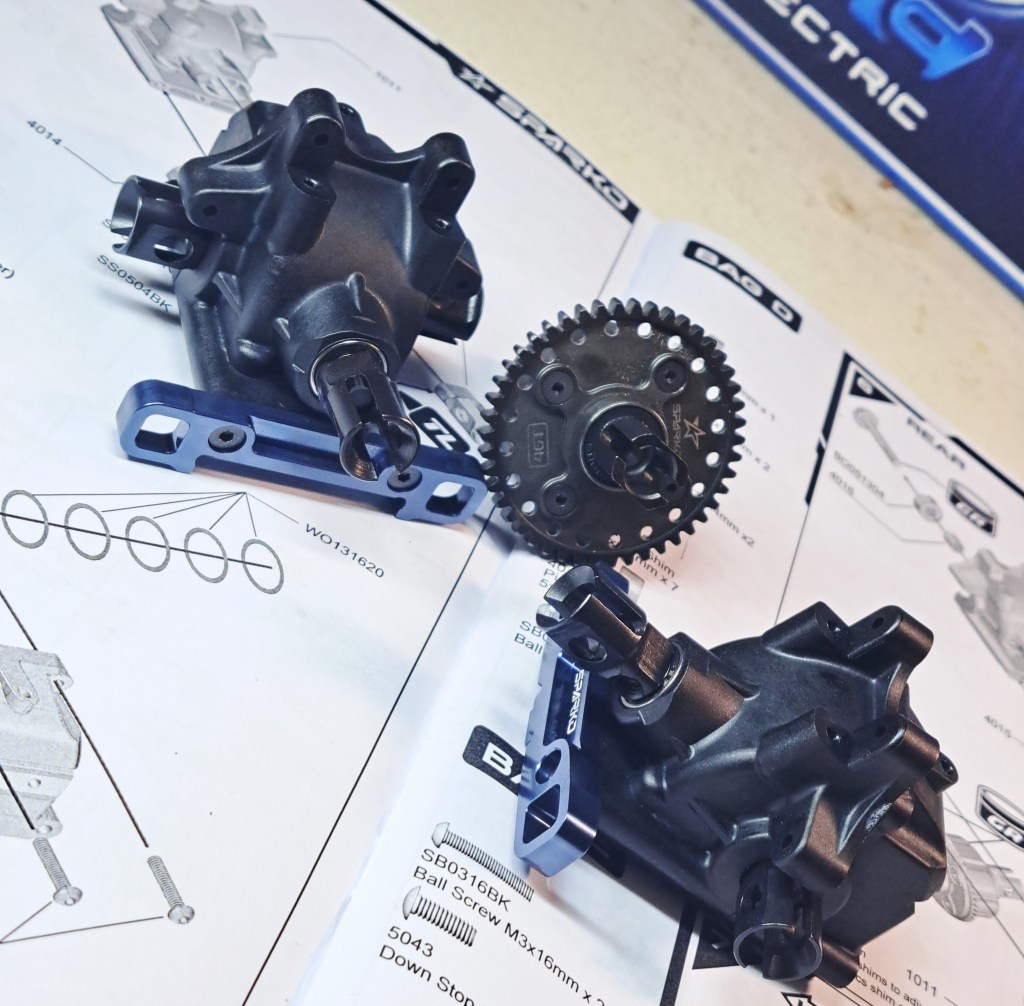

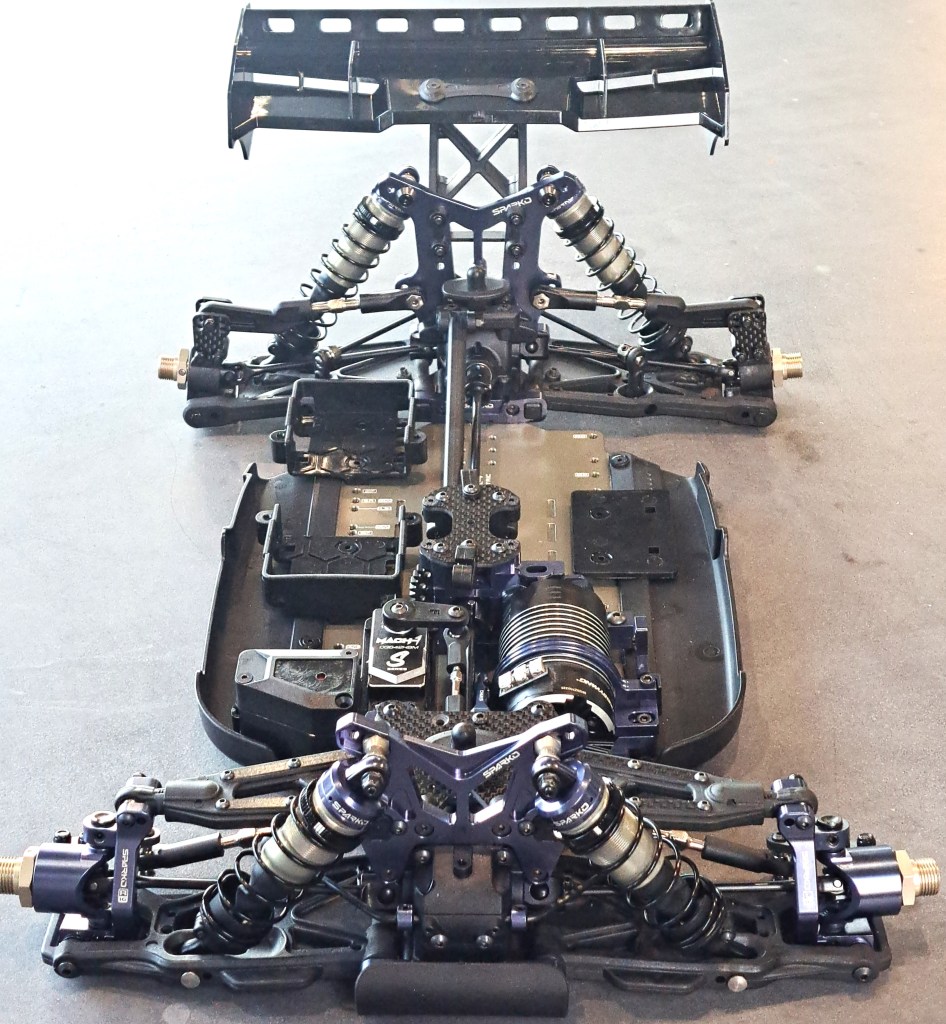

As I built the F8e, I couldn’t help but notice just how extraordinary modern materials and engineering are. Sparko’s machined aluminium parts, for example, are a testament to contemporary manufacturing technology. The team from Sparko have clearly paid attention to the standards expected in the market, and the F8e lives up to those expectations when it comes to material choices.

The build includes all the setup/geometry tweak options you’d want – inserts in the A, B, C and D blocks enable changes to anti-dive/anti-squat, track width, and plenty of options around roll centres, axle heights and so on.

I also appreciated the options for cable routing – including multiple clips and cable retainers that can be used in various locations to keep motor, battery and radio cabling neat and tidy (and well away from drive shafts and spur gears).

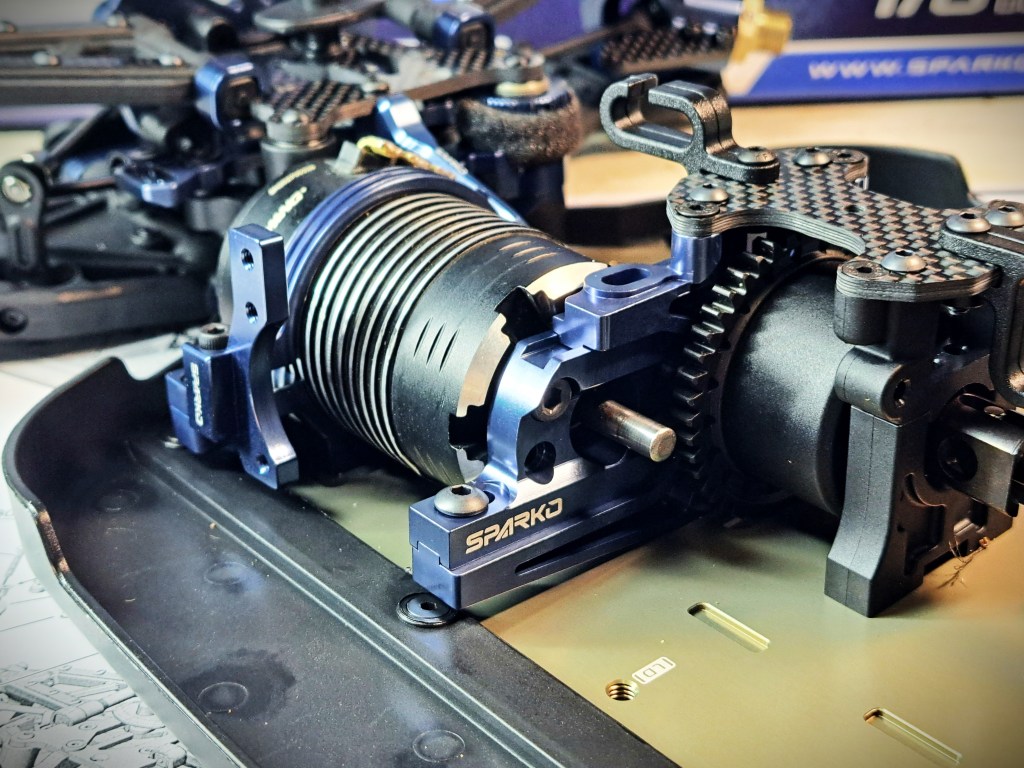

The motor mount itself is an absolute work of art. It’s a multi-piece affair and holds the motor firmly at both the front and rear of the motor. The rear clamping ring also includes an integrated fan mount for running in high-temperature conditions.

Like any serious race-car engineer, Sparko has certainly pushed some things to the limit. Clearance between the steering bell-cranks and front diff outdrive, for example, is tight. The nitro version of the car, making room to package the engine, fuel tank and a larger radio box pushes that bellcrank to the outside of the car – but in the F8e it’s central, and therefore tightly packaged. The receiver box is another example of this – there is “just” enough room for a receiver and transponder in the dedicated receiver box – it’s brilliant (the integrated transponder mount in particular), but does push the edge of being too tight if you have a larger receiver. My Sanwa RX482 just fits.

THE DETAILS

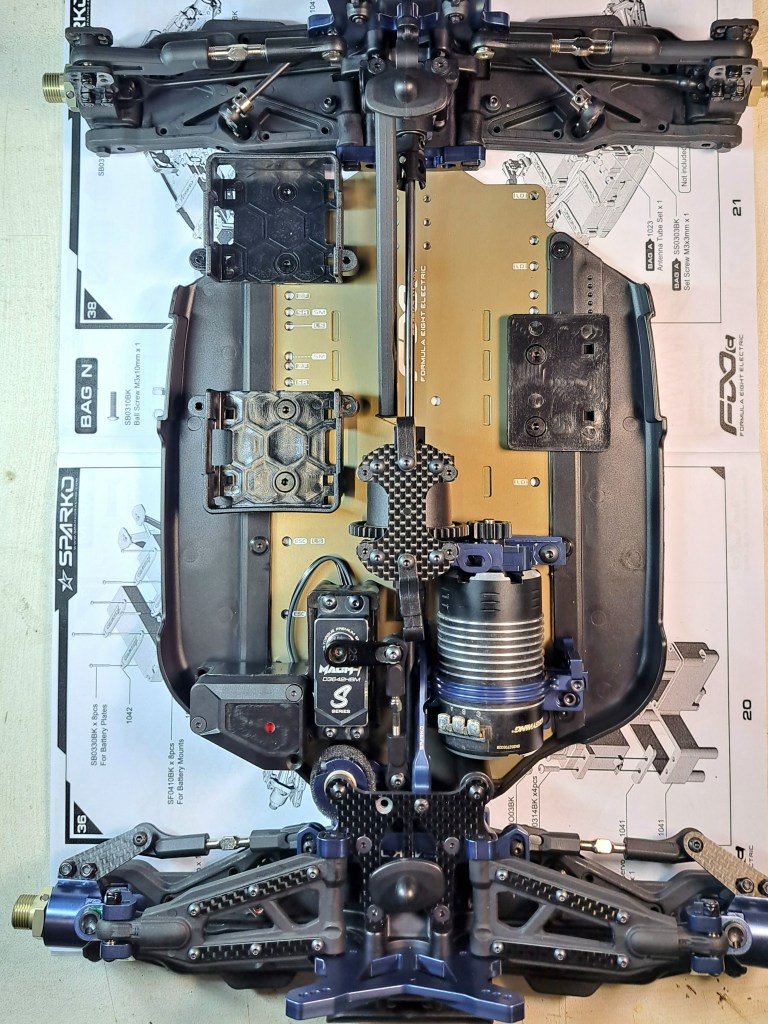

I mentioned earlier that we’d come back to the choices Sparko have made regarding battery, motor and ESC layout within the chassis. One of the things I like about the Sparko approach is that the kit includes all the parts needed to run either saddle or brick packs (in either shorty or full-size format). The instruction manual suggests the saddle-pack route as the standard – and to be fair that’s going to offer the most balanced weight distribution.

For those bringing a set of 4s brick packs with them – like me with my DXF 6500 4s packs, it’s easy to reconfigure the car to suit those batteries. In my case, I’ve installed the DXF pack and Mach-1 servo down one side, and the Hobbywing ESC and motor down the other. The battery is set well back on the chassis, and it might be interesting to experiment with either other placement options, or a shorty pack at some stage.

Battery retention is by either plastic straps or velcro strips, depending on the size and shape of the batteries you opt for. The battery itself sits up a little off the chassis – that’s good for making sure it doesn’t interfere with chassis flex, but perhaps not quite so ideal in terms of centre of gravity.

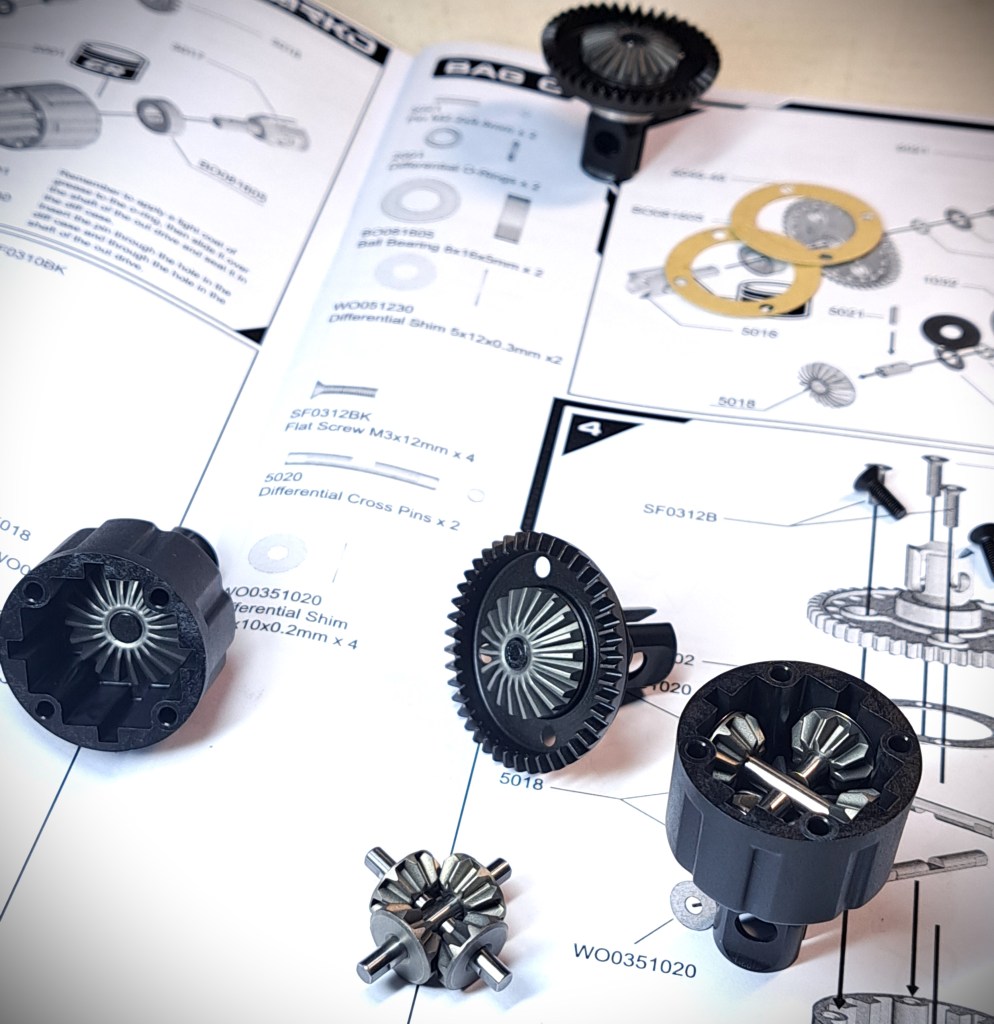

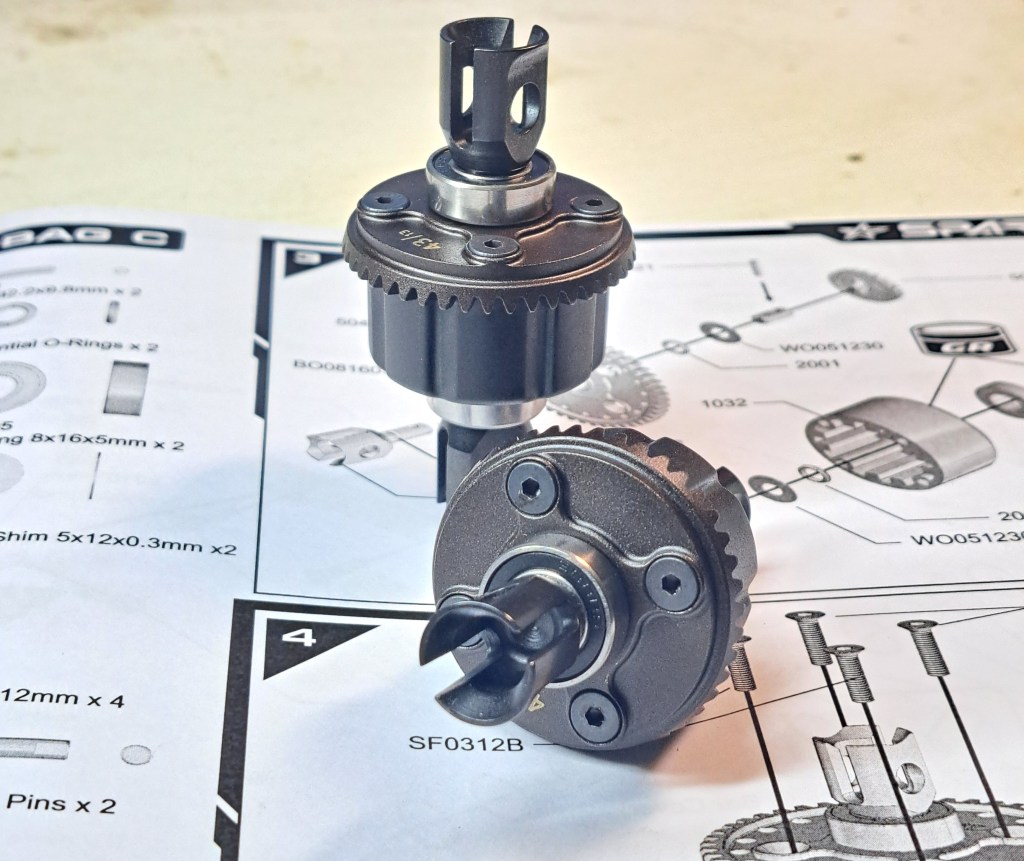

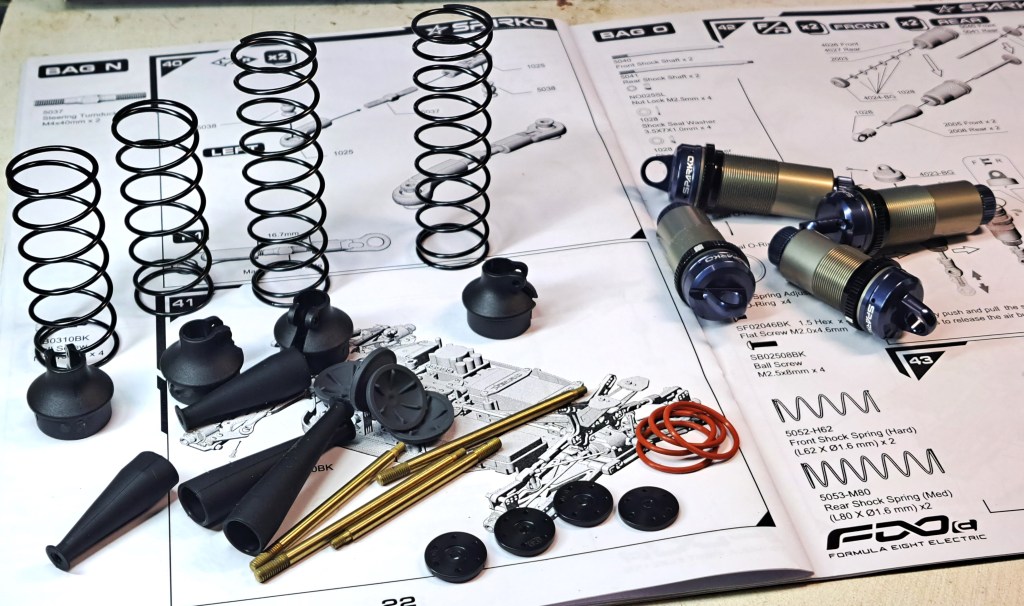

There are a bunch of small details in the build that are appreciated. I reached out to a group of Sparko owners to see what they had appreciated both in the build and in running the cars. Marked spring pre-load collars, making for easy, repeatable adjustments is one thing that got a mention, the built-in motor fan mount is another. Shock caps that feature bleed options, and an included wing with optional height, angle and three different wicker options were others. I noticed the keyed diff pins, and machined chassis recess for steering posts as a couple of other small details I appreciated.

THE BUILD EXPERIENCE

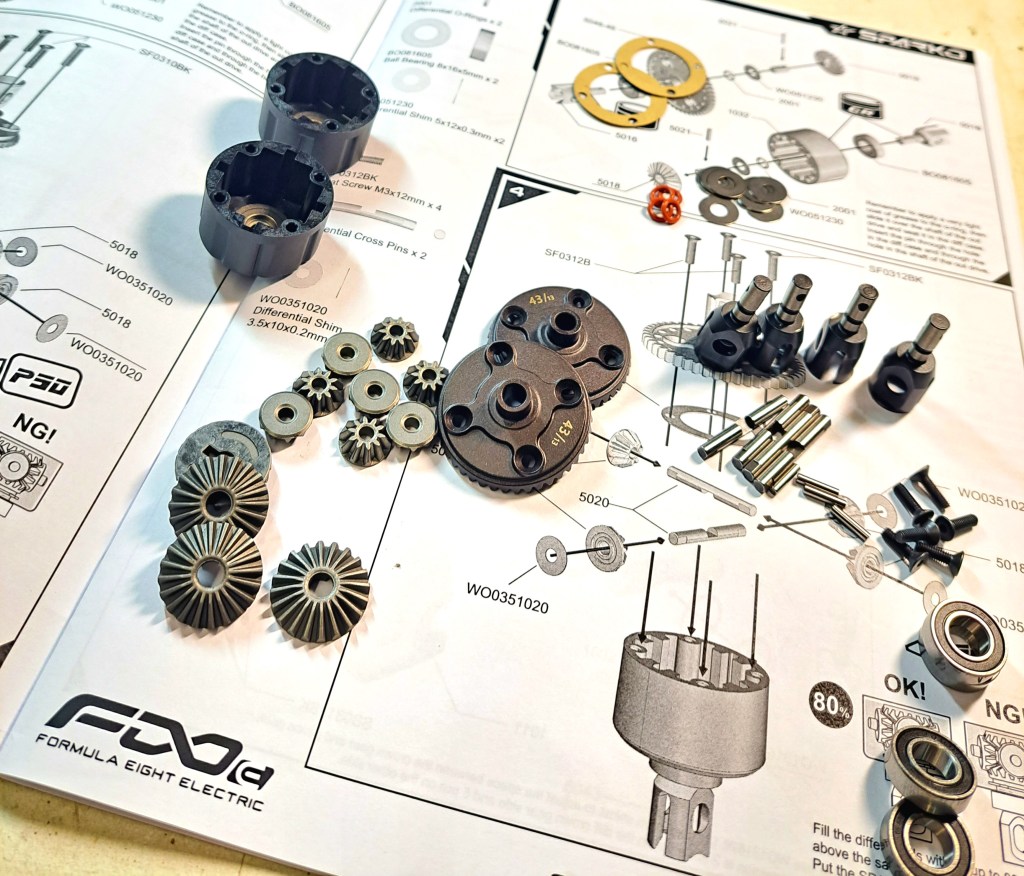

If you’ve built an 8th buggy before, the F8e build won’t hold any surprises. Fit and finish are good – noting that there are a couple of tight clearances I mentioned earlier, and the car went together easily and well over a few nights as I found time. The kit includes all the fluids you’ll need to build up with a kit setup – and I’ve opted to throw that absolutely kit-standard setup on the car as a starting point for my driving and testing experience. In terms of fluids, that means 600cst in both front and rear dampers and 10k/10k/5k in front/centre/rear diffs respectively. The kit also includes a couple of different sway-bar options for both front and rear to help dial things in for your track conditions. Again, I’ll start with the kit-recommended option before I go tuning. We’ll obviously land in different spots for different track conditions – my two closest tracks at Logan and Pine Hills are very different to one another.

As a first kit offering from Sparko, the F8/F8e is a solid effort and I enjoyed the build process. The instruction manual itself could offer a little more information in a few places – and doesn’t include much in the way of tuning tips or information. Adding something like the Hudy Setup Guide, or JQ’s Invisible Speed book to your knowledge base will be a useful addition for any racer when it comes time to tune the F8e. I’m guessing Sparko will improve in this area for future releases. There are also active owner groups already out and about, sharing setup and tuning tips, along with setup sheets from pro racers like Ryan Pavidis and Ryan Cavalieri. In Australia, distributor Speedy RC is helping to make sure owners can connect, share info and get the cars tuned in for local conditions. That’s the kind of support I value.

I did have a couple of little challenges in the build, easily resolved with a bit of careful thinking, and on one occasion a quick chat with Speedy RC. If you look closely at the photos, you might spot one area where I got things a little out of whack (I’m not telling you where…you can figure it out!) but spotted my error before heading to the track. One tip is to be very careful to use the right length screws at each step. Consult the manual carefully, and measure to make sure you have the clearance you need. I already mentioned the tight clearance of the steering bellcrank with the front diff outdrive, and I opted for a low-profile nut in that location to offer a tiny bit more room.

I’m starting with the kit-standard plastic steering servo arm, but expect I’ll swap that out for an alloy one as soon as I’m able to get my hands on a suitable option. As you can see in the photos, I finished out the build with my Mach-1 RC Products servo, DXF Batteries Australia packs, Hobbywing motor and ESC, a set of Jetko Power tyres, and a beautiful body courtesy of the airbrush of painting wizard JKRacing.

READY FOR THE TRACK?

All of that brings me up to the fun part – getting this buggy on the track. Time and weather interfered with my planned first runs. Proper testing and first race meetings will take place over the next few weeks.

That said, one rainy day with weather threatening I zipped down to Brisbane’s Logan track and threw the F8e onto the track for a couple of packs before the rain tumbled and the day was suspended. On a freshly rebuilt track, in very favourable (damp, good grip) conditions, the F8e was an absolute joy to drive. Power down, turn-in, on-power steering, stability under brakes, jumping….the lot. In those conditions it was the best buggy I’ve driven…and it left me very keen for more track time. Now two break-in packs is not a track test, and nearly any car would have performed in those conditions…but it felt good!

We’ll be back in a month or so with a story from some more extended running, and hopefully a first club race or two. We’re hoping to be in Toowoomba for the King of the Mountain race in late May as well. That track testing will include exploring some of the commonly used optional parts – we’ll sub out the standard shock diaphragms for an emulsion build, for example, and change out the standard front arms for the optional upper link conversion.

For now, it’s been a good experience to get the F8e track ready, and I’m looking forward to the weeks and months ahead. If you’re interested in giving one a whirl, touch base with the team at SpeedyRC Online Store.

Leave a comment